Differences between Fiberglass Windows and Vinyl Windows

Contents

Fiberglass and vinyl windows[edit]

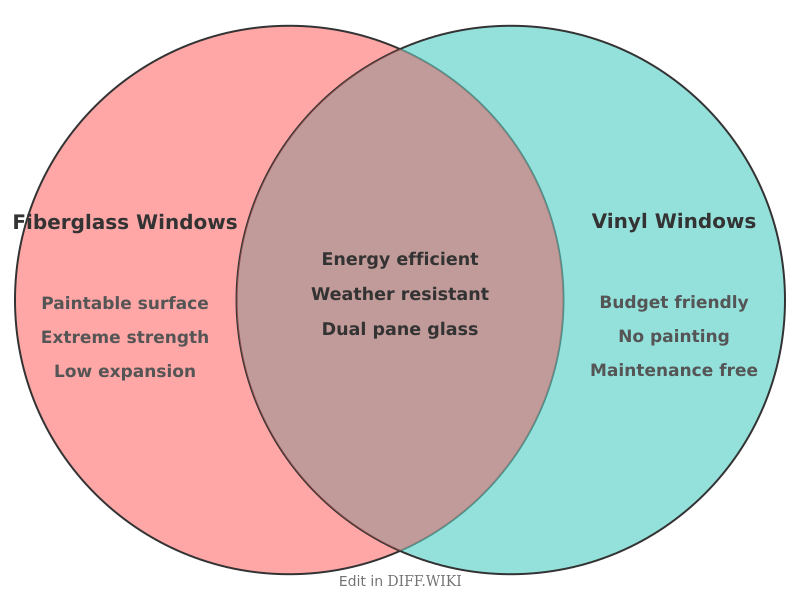

Fiberglass and vinyl are two of the most common materials used for modern residential window frames. While both serve as alternatives to traditional wood or aluminum, they differ in chemical composition, structural performance, and cost. Vinyl windows, made from polyvinyl chloride (PVC), became a dominant market force in the late 20th century due to their low production costs. Fiberglass windows are manufactured through a process called pultrusion, where glass fibers are pulled through a resin bath and heated to create a rigid material.

Material composition[edit]

Vinyl window frames consist of extruded PVC, which often includes stabilizers and pigments to prevent UV degradation. The frames are hollow but may be divided into multiple chambers to improve thermal insulation. Fiberglass frames are made of glass fibers and polyester resins. Because fiberglass is composed of the same primary material as the glass panes it holds, the frame and the glass expand and contract at nearly the same rate during temperature changes. This reduces stress on the window seals compared to vinyl, which has a significantly higher coefficient of thermal expansion.

Comparison table[edit]

| Category | Vinyl windows | Fiberglass windows |

|---|---|---|

| Base material | Polyvinyl chloride (PVC) | Glass fibers and resin |

| Estimated lifespan | 20–30 years | 30–50 years |

| Thermal expansion | High (frequent expansion/contraction) | Low (similar to glass) |

| Paintability | Typically cannot be painted | Can be painted and repainted |

| Structural strength | Flexible; requires thicker frames | Rigid; allows for thinner frames |

| Relative cost | Generally lower | Generally 20% to 30% higher |

| Maintenance | Low; never needs painting | Low; may require paint touch-ups |

| UV resistance | Can become brittle over time | High resistance to UV rays |

Performance and maintenance[edit]

The structural integrity of fiberglass allows for thinner frame profiles, which increases the visible glass area. Fiberglass is approximately eight times stronger than vinyl, meaning it does not require the same level of internal reinforcement to support large or heavy panes of glass. This rigidity prevents the frames from warping or sagging in extreme heat, a known issue for some lower-grade vinyl products.

Vinyl windows are favored for their maintenance-free nature. The color is consistent throughout the material, so scratches are less visible, and the frames do not require painting or sealing. However, vinyl is susceptible to thermal "pumping," where the frame pulls away from the wall or the glass unit due to temperature fluctuations, potentially leading to air leaks over several decades. Fiberglass frames can be painted to match specific architectural designs, whereas vinyl windows are generally limited to a few factory-standard colors, such as white or tan.

Cost and availability[edit]

Vinyl remains the more accessible option for many homeowners because of its lower price point and widespread availability through big-box retailers and local contractors. Fiberglass windows are often positioned as a premium product. While the initial investment for fiberglass is higher, manufacturers often cite a longer expected service life and better long-term energy performance as justification for the price difference. According to the U.S. Department of Energy, both materials provide better insulation than standard aluminum frames, though the specific U-factor of a window depends more on the glass type and gas fills than the frame material alone.

References[edit]

- U.S. Department of Energy. "Window Types and Technologies." Energy.gov.

- International Association of Certified Home Inspectors (InterNACHI). "Window Materials."

- American Architectural Manufacturers Association (AAMA). "Material Performance Standards for Vinyl and Fiberglass."